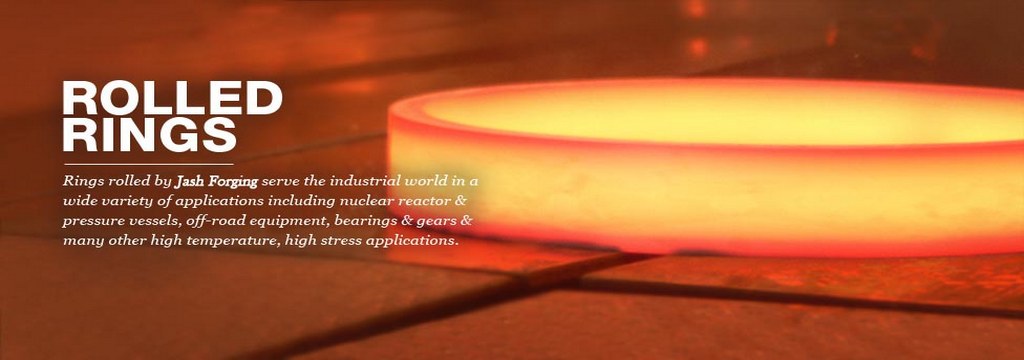

Forging Process

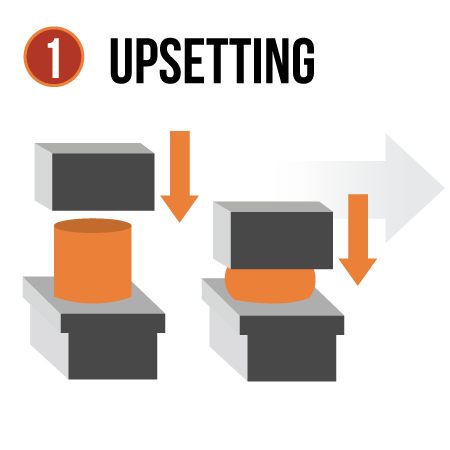

The ring rolling process begins with the upsetting of the starting stock on flat dies at its plastic deformation temperature.

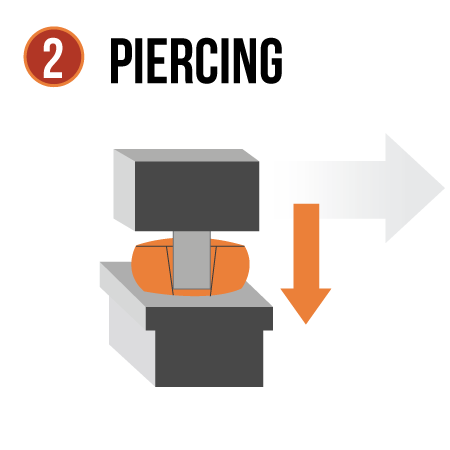

Piercing involves forcing a punch into the hot upset stock displacing metal radically and leaving a thin web of metal at the bottom.

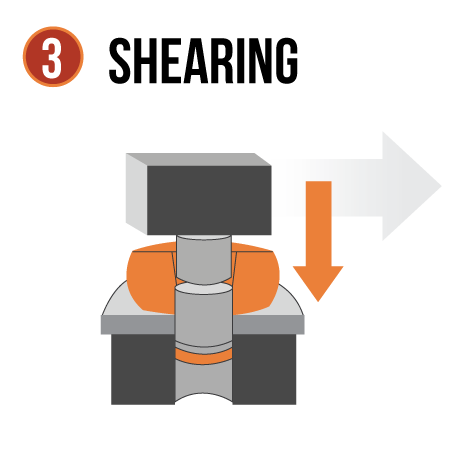

A subsequent operation, shearing, removes the thin web producing a completed hole through the stock.

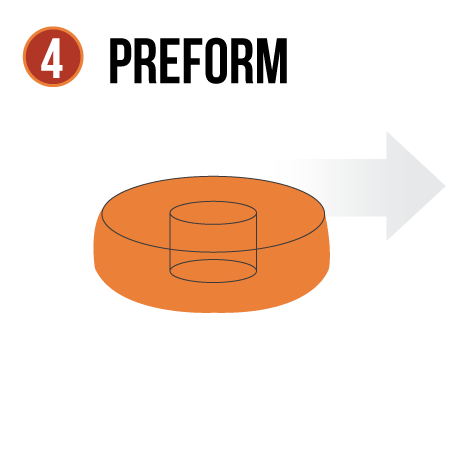

This stock, referred to as a blank or preform, is now ready for the ring rolling process.

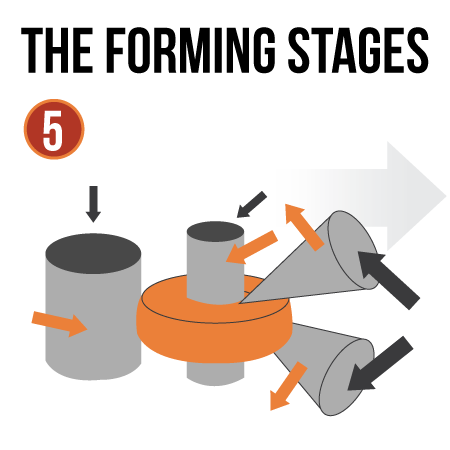

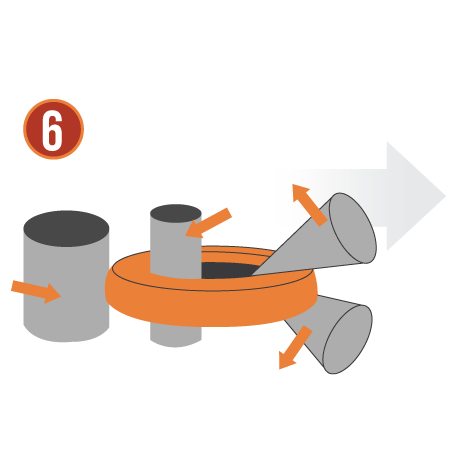

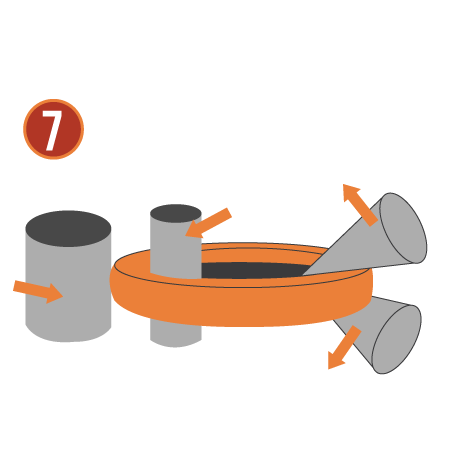

The donut-shaped preform is placed over the mandrel.

As the preform is rotated in the mill, the mandrel begins to apply pressure toward the main roll. At the same time, the axial cones apply pressure toward each other.

As a result of the radial and axial pressure, the ring's OD and ID gradually increase while the thickness and wall section are reduced.